Texas A&M Team Competes In Final Phase Of GoFly Challenge

A team in the Texas A&M University Department of Aerospace Engineering worked over the past two years to make personal flying vehicles a reality as part of the GoFly Prize competition sponsored by Boeing.

The GoFly Prize, a two-year, $2-million international competition to create a personal flying device, launched in September 2017 and had almost 3,000 innovators across 110 countries compete in Phase I. The challenge was to create a device that can be flown by anyone, regardless of experience, 20 miles without refueling or recharging with vertical, or near vertical, takeoff and landing capability.

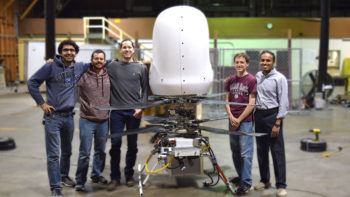

Under Moble Benedict, associate professor in the Department of Aerospace Engineering, a team of eight Texas A&M aerospace engineering graduate students and two researchers from NASA created “Harmony.” As outlined in their written report, Harmony is a compact rotorcraft designed to minimize noise and maximize efficiency, safety, reliability and flight experience. As part of Phase I, the team built a 1/8 scale prototype to demonstrate their vehicle design. They were awarded $20,000 as one of the 10 winning teams in Phase I and went on to build a prototype, named Aria, to win the $50,000 prize for Phase II. The Texas A&M team was the only United States university team out of the five Phase II winners.

“Winning both Phases I and II of the GoFly Prize, especially with such fierce competition, brought a lot of excitement and confidence to the team,” Benedict said.

Phase II involved hundreds of hours of lab testing to successfully verify their full-scale aerodynamic and acoustic predictions.

“Although the hours have been long and exhausting, I’m very excited about GoFly,” said team member Farid Saemi. “I would not have enjoyed such a hands-on opportunity to develop a new field of aviation even if I had gone straight to industry as a recent graduate.”

Throughout the process, the team worked to address practical issues like the size of the personal flying vehicle and the high noise levels generated. The vehicle had to be less than 8.5 feet – something that can fit in a garage and take off almost vertically.

“Helicopter rotors are very big because of the trade-off between efficiency vs. compactness of a rotor,” Benedict said. “We have carefully chosen a configuration that can give you very high efficiency for the given footprint.”

To address the noise, the team shaped the blades to minimize the rotor noise as much as possible. At 73 decibels 50 feet in the air (the equivalent of highway noise in a car), Aria was also the quietest prototype at the competition and is also believed to be the quietest rotorcraft in the world at this size scale.

The final personal flying vehicle had to be capable of carrying a payload of 200 pounds and travel at a speed of at least 30 knots. Because the team’s vehicle crashed during a flight test 10 days prior to competition, they were only able to fly their one-third scale prototype for Phase III in February 2020. However, Harmony was one of the four teams that could fly at any scale during the final fly-off.

Since none of the competing teams could meet the GoFly requirements in the final fly off, the competition still remains open. Benedict and his team at Texas A&M intend to continue competing for the $1 million grand prize provided they can obtain university support to build the next prototype. Based on the new GoFly rules due to the COVID-19 pandemic, the flight capabilities of their new prototype could be demonstrated at the RELLIS Campus.

Benedict is confident that had the team flown the full-scale model, they would have won the competition; he intends to compete in the next GoFly phase with a stronger and more innovative prototype. They’re currently analyzing what they’ve learned from the GoFly competition to improve their design in the next competition. Since its Phase II success, the team has also built and successfully tested both the one-third scale prototype (22 pounds) and the full-scale prototype (550 pounds).

“The visibility and success the team has had from the GoFly challenge has put Texas A&M on the map for eVTOL (electric vertical takeoff and landing) aviation,” Benedict said. “This also paved the way for two research grants we recently obtained, one from the Army Research Lab on hybrid-electric aviation the other from Air Force’s Agility Prime Program to develop quiet propulsors for eVTOL aircraft.”

Texas A&M team members include David Coleman, Farid Saemi, Carl Runco, Atanu Halder, Bochan Lee, Hunter Denton, Vishaal Subramanian and Benedict. More information on Benedict’s research can be found at his website.

This article by Laura Simmons originally appeared on the College of Engineering website.