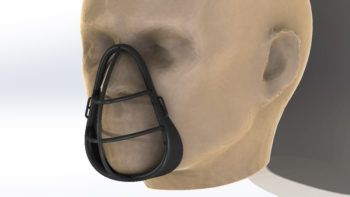

Students Create Frame For Interchangeable Face Coverings

A team of Texas A&M University students has created a superior alternative to homemade face coverings to protect against the spread of the novel coronavirus. Their product, which is funded by the National Science Foundation’s (NSF) I-Corps Site program, also provides a safer user experience.

“To alleviate the demand for medical-grade face masks, conserve N95 masks for medical workers and provide a dependable, reusable and inexpensive face mask to the general population, our team designed the EASYMASK,” said Noble Gutierrez ’22, a student in the J. Mike Walker ’66 Department of Mechanical Engineering. “The EASYMASK concept provides a better seal and protection than disposable and homemade masks and utilizes common materials found at home as filters.”

Gutierrez is a member of the team that created the EASYMASK during the Aggies Against COVID-19 Virtual Competition. His team members are Ian Suarez, Veronica Perez, Sterling LaBoo, Cecilia Torres and Thomas Goodwin. Half of the members are engineering students, while the other half are public health students.

The product’s success provided eligibility into the NSF I-Corps Site program. Through this program, students receive guidance and funding to take their products from conceptualization to the market.

“Our team received an email invitation from the NSF I-Corps Site program following our top-10 placement in the Aggies Against COVID-19 event,” Gutierrez said. “We were grateful for the opportunity to explore market potential.”

The product is a mask frame that combines comfort with sustainability, allowing users to interchange the mask filters with typical household items.

“Common household fabrics can be as effective as surgical masks in the filtration of particles depending on the combination and layering of materials,” Gutierrez said. “The EASYMASK’s simple frame allows the user to insert their own filters made from fabrics that can be easily, frequently and inexpensively replaced. The mask eliminates the compulsory need for users to regularly adjust their masks, reducing the risk of contamination.”

To receive further funding through the program, the team had to conduct market research and adapt their product based on feedback. The COVID-19 pandemic’s impact required the students to complete most of this work virtually.

“I facilitated our product design requirement features, conducted all 30 customer interviews and program presentations,” Gutierrez said. “COVID-19 turned our entrepreneurship experience virtual, and our team was incredible. We were fully committed, cooperative and continued to develop our product. It was a tremendous pleasure to work with eager and capable team members to address the global humanitarian crisis.”

The team will continue working on their product with the NSF I-Corps Site program to develop their prototype and aid in the fight against COVID-19.

This article by Michelle Revels originally appeared on the College of Engineering website.