Stopping SARS-CoV-2 Along The Farm-To-Plate Supply Chain

From live cattle entering a packing plant to the consumer’s kitchen table, a Texas A&M AgriLife-led research project aims to develop an accurate way to predict potential contamination with SARS-CoV-2, the virus that causes COVID-19, throughout the food supply chain.

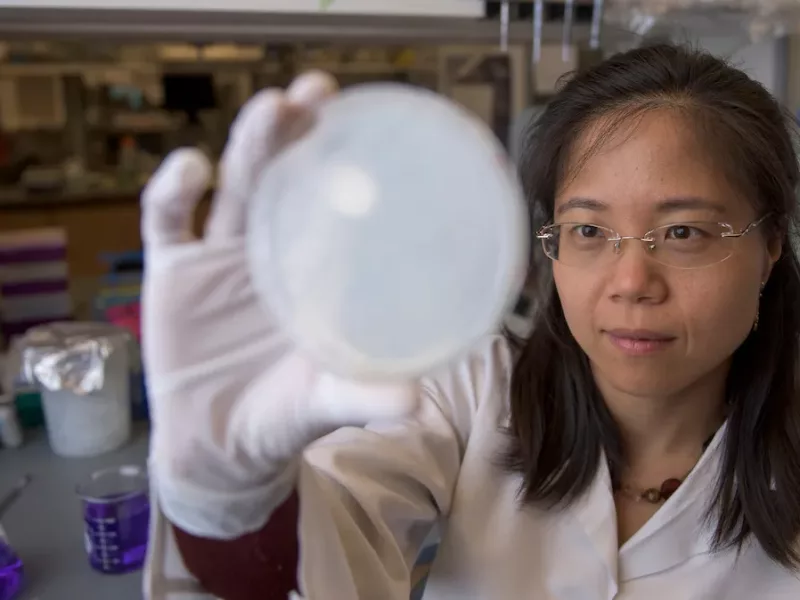

Sapna Chitlapilly Dass, a meat science research assistant professor in the Texas A&M College of Agricultural and Life Sciences Department of Animal Science, will lead the two-year, $1 million U.S. Department of Agriculture National Institute of Food and Agriculture grant project.

The project is a collaboration of Texas A&M AgriLife Research; Texas A&M Veterinary Medical Diagnostic Laboratory, TVMDL; Texas A&M AgriLife Extension Service; the USDA-Agricultural Research Service’s U.S. Meat Animal Research Center, Nebraska; and the University of Pennsylvania.

“This research is an example of how Texas A&M is addressing SARS-CoV-2 issues throughout the food chain to improve agriculture and human health,” said Patrick J. Stover, vice chancellor of Texas A&M AgriLife, dean of the College of Agriculture and Life Sciences and director of AgriLife Research. “Upon completion of this research, each segment of the supply chain will know where the virus hot spots might lie and how best to mitigate them. By bringing together our agencies and the College of Agriculture and Life Sciences, AgriLife can address these issues as comprehensively as possible.”

To date, most studies on deciphering the cause and transmission of SARS-CoV-2 in meat production have based their understanding on just one aspect of the meat processing chain, Dass said.

Now, the team of researchers will investigate the susceptibility to and transmission of SARS-CoV-2 in beef cattle, identify the impact of the virus on different phases of meat processing and packaging, and follow up to determine the virus’s survival rate on meat and packaging material during transportation and in retail conditions.

Beef Cattle Investigation Of SARS-CoV-2

“Ultimately it is the safety of all the people along the food chain that matters,” said Cliff Lamb, head of the Department of Animal Science, who will provide guidance on the live animal experiments. “We need to know if these animals can contract the virus, whether they show symptoms or not, whether they can shed it and spread to other animals, and whether they can spread it to humans.”

According to the Centers for Disease Control and Prevention, SARS-CoV-2 appears to be transmissible from people to animals in some situations, and the reverse is also a possibility.

Because other mammals have tested positive for COVID-19, and because cattle have been known to contract a different coronavirus strain, testing is crucial, Lamb said.

“We need to determine if cattle would actually contract it and if they would be able to spread it from animal to animal,” he said. “We don’t think they will contract the disease or spread it, but at the same time, we want to rule that out.”

Lamb said once the research is complete, a farm-to-plate education program through AgriLife Extension will be led by Jason Smith, beef cattle specialist in Amarillo.

Smith and his team will work on ensuring instructional videos, fact sheets and other educational materials are distributed to all stakeholders along the farm-to-plate food chain.

“We want to educate everyone — from the cow/calf owner to the stocker operator to the packing plant to the retail store — and make them aware of where the hotspots are and how the virus can be spread,” he said. “Our ultimate goal with this research is to educate people on how to reduce their risk of contracting the virus.”

Addressing The Biggest Bottleneck With Science

Early in the pandemic, the meat industry’s production suffered bottlenecks as health and industry officials tried to grasp where and how workers were contracting the virus and whether that might impact the facility’s products.

“COVID hit meat processing plants hard, with many workers affected and plants closed,” said Amanda Brown, an associate professor for research who holds a joint position with TVMDL and the Department of Animal Science.

“This resulted in concerns regarding the supply of meat, with some stores implementing sales limits. There have also been stories in the national and international press concerning the potential of the virus surviving on food and food packaging — especially meat,” Brown said. “Our hope is this project will lead to practical methods of ensuring our nation’s meat supply is stable and sustainable.”

Dass said the concern is that microorganisms are keeping the virus alive in hot spots and circulating as super spreaders. Different microbial communities within the processing plant can either encourage or inhibit the virus particle to be part of a sanitizer-tolerant biofilm and contribute to recurrent contamination.

Further research is needed to understand SARS-CoV-2 survival and transmission in the beef supply chain, she said. This will help develop effective intervention strategies as well as educate livestock producers, food handlers and consumers on safe food-handling practices.

Employing High-Containment Diagnostics Facilities

The project will rely on TVMDL’s Biological Safety Level-3, or BSL-3, virus propagation expertise and high-containment facilities, in addition to projects currently underway in TVMDL’s research and development section.

Since its establishment last year, TVMDL’s research and development section has focused on creating new methods of rapid, molecular diagnostics. Once fully established, these methods will be used chute-side and in meat processing plants on environmental samples for COVID-19.

“The research and development section is excited to further the practicality of our current research interests,” Brown said. “By incorporating our current interests with those this new project aims to address, we are hopeful our work can assist a broader scope of individuals and allow for a better understanding of COVID-19.”

A Comprehensive Examination Of SARS-CoV-2

Dass said her research will include the use of live virus in the new Texas A&M University Global Health Research Complex on the Texas A&M campus. This $86 million omplex was created to combat emerging disease threats, and is a nationally distinct facility and core laboratory. This facility has Institutional Animal Care and Use Committee approval.

In partnership with the Massachusetts Institute of Technology’s, MIT, STOPCovid initiative, the team will utilize CRISPR-based diagnostics for COVID-19, with the initiative’s newly established SHERLOCK research protocol. SHERLOCK-Covid is a research-use-only assay that has been made available to researchers via STOPCovid. With SHERLOCK, a strip of paper can now indicate presence of pathogens or any genetic signature of interest.

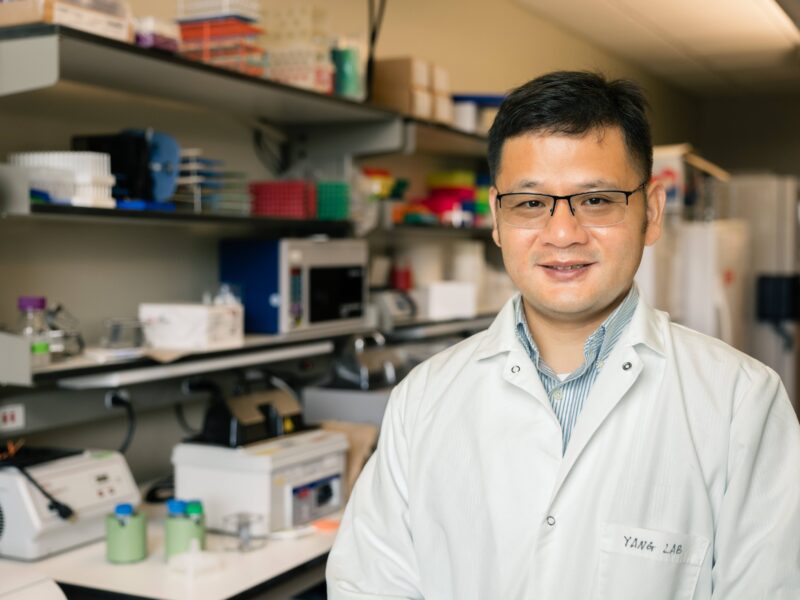

Dass said the team also includes biophysicist Arnold Mathijssen, assistant professor in the Department of Physics and Astronomy at the University of Pennsylvania. Mathijssen will help develop the mathematical modeling and study the transmission dynamics of SARS-CoV-2.

Following the data gathering steps, the researchers plan to develop a mathematical model to predict the potential for food contamination with SARS-CoV-2, Dass said.

“Using this mathematical model, we aim to predict the probability of SARS-CoV-2 spread among livestock if one is infected,” she said. “Based on our observations about the transmission potential among individual cattle, we will forecast the viral percolation across a large group of animals.”

This will also put benchmarks on the risk of SARS-CoV-2 infection to farm personnel, Dass said.

“We have so many stakeholders who want to get these answers as soon as possible to ensure the workforce, as well as the food supply, remains safe,” Dass said. “When complete, we will be able to provide key information about the risk of SARS-CoV-2 infection, its impact on beef consumers, and the effect on personnel across the meat industry, including farmers, processors, packers and retailers.”

This article by Kay Ledbetter originally appeared on AgriLife Today.