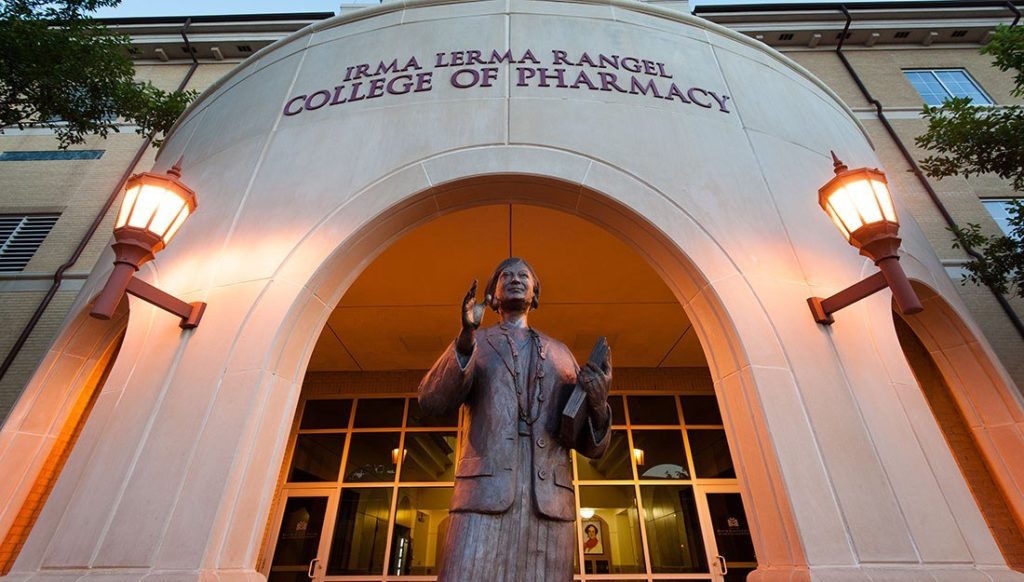

When we take a medication, we assume it is safe, that it has no stray contaminants and that it really does have the chemical that we think it does, and in the amounts stated on the label. The same is true—and perfect dosing might be even more important—when creating a drug for human clinical trials. That’s why these products need to be created in what is called a good manufacturing practice laboratory, or GMP for short. “We must make a product in a GMP laboratory in order to administer it to humans,” said Mansoor A. Khan, RPh, PhD, professor and vice dean of the Texas A&M Irma Lerma Rangel College of Pharmacy College Station campus.

Soon, that campus will have a small academic GMP of its own, expected to open in June in the Reynolds Building on Texas A&M University’s campus. This is a first-of-its-kind facility for the Texas A&M College Station campus, because although liquid forms like injections can be manufactured in a current facility at the National Center for Therapeutics Manufacturing, until now, there was no place to formulate other dosage forms. This small new facility will help create solid dosage forms such as immediate and modified-release capsules and tablets, novel drug delivery systems including nanoparticles and topical products such as ointments or creams for animal or human testing under rigid regulatory protocols.

“This facility will dramatically increase our opportunities for research leading to translations of our discoveries into commercially viable pharmaceutical dosage forms,” Khan said. “It will help us, as a university, convert Texas A&M scientists’ discoveries of chemicals to potentially life-saving drug formulations for testing in animals and humans.”

Center For Population Health And Aging Opens, Formalizes Texas A&M Collaborations

This is because there is a long road between the discovery of a potentially medically useful compound and actual approval as a new pharmaceutical. “A patient does not take a pure chemical by itself, rather a dosage form such as a tablet or a capsule that contains chemicals,” Khan said. “We need an ability to have dosage forms for testing.”

Although faculty members with a potential drug candidate could contract out with a GMP lab to create their tablet or capsule, that process has little room for the trial-and-error of product refinement. “When you do that, you have to give them a defined formula, a defined product,” Khan said. However, it is difficult to have a final formula without a great deal of preliminary testing and evaluation, and that’s where the new lab and the College of Pharmacy can help with a thorough product understanding, feasibility and potential for commercialization, intellectual property development and proper documentation before expensive clinical trials.

“This new facility will truly be a resource for all Texas A&M faculty members in every college,” said Indra K. Reddy. PhD, founding dean of the College of Pharmacy. “It will help spur collaborative efforts to develop new and potentially life-changing or even life-saving drugs.”

Any GMP must follow specified lighting, plumbing, sewage and washing facility requirements. “From the outside, it will not look any different from any other laboratory,” Khan said. “But it requires lots of very specific equipment and a very controlled environment, including space for different stages of the process to be distinctly separate.”

To be recognized by the Food and Drug Administration (FDA) as a GMP lab, there are extensive requirements, not only for the facility itself, but also for recordkeeping, personnel qualifications and training, sanitation, cleanliness, equipment verification, process validation and thorough documentation.

“We at Texas A&M are very good at synthesizing a new chemical or extracting one from a natural source,” Khan said. “Our scientists across the university may have discovered chemicals to treat diabetes, cancer, or many other serious conditions, and now they will have a way to create a viable pharmaceutical product that can go into veterinary or human clinical trials, which is the critical regulatory first step to convert Texas A&M discoveries of life-saving drugs into commercializable pharmaceutical drug formulations.”

###

This story by Christina Sumners originally appeared in Vital Record.